The REDEB support brackets/consoles and the SOFFIT multiform panels/platforms for loads under 1.5 or 2 tonnes per console depending on sheet pile type, are designed for capping sheet piles without the need for welding or drilling the sheet pile (except for some 700 mm wide AZ piles).

Caps weighing up to 3 tonnes per console can be achieved by using special equipment (location button and MDBS).

This system can also be used for capping mixed curtain walls.

Operation

Before pouring

1) Position the REDEB brackets as specified in the “Mounting REDEB brackets” chapter. Check they are at the correct height, that the bolts are torqued up correctly (to 180Nm) and that they are horizontal using a spirit level.

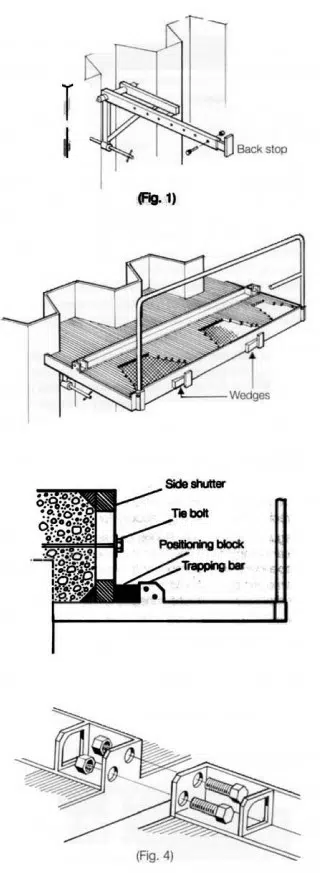

2) Fix a back stop inside the end of the longer arm and bolt it onto the bracket (see fig.1).

3) Lower the SOFFIT panels onto the brackets. Ensure where possible that the front edge of the panel is tight up against the outside edge of the sheet piles. Use timber wedges to drive the panel forward against the sheet pile face, i.e. drive them between the back stop and the panel. This prevents the Soffit Panels from moving backwards.The back stops also take any horizontal load in this direction (fig.2).

4) The guard rail is an integral part of the panel.

5) Using a hammer, lightly tap the ends of each of the stainless steel bars until they have all been pushed hard up against the sheet piles; start by tapping the bars into the center of the pan of the piles and then work outwards. Lubricate the bars generously with shutter oil.

6) The side shutters can now be positioned straight onto the top of the Soffit Panel bars. The trapping bar member on the top side of the panel can be used to aid positioning of the side shutter. (fig.3). However, the horizontal load exerted by the wet concrete should not be taken by the Panel, but by some other method, such as ties passing through the concrete and fixed to the sheet piles.

7) Any small gaps between the soffit bar ends and the sheet pile can be filled with Hessian or other filler plugs to prevent grout leakage.

8) Use shuttering or mold oil on the bars to minimize any adhesion from the concrete.

9) Join the panels together using the supplied bolts (fig.4).

After pouring

1) After 36 hours, the brackets and panels can be removed.

2) Use the leveling bolt to lower the bracket so that the Soffit panel can be removed. Now the fast release can be used to dismantle the bracket in a single action.

3) The lifting of the Soffit Panel will automatically cause free movement of the steel bars, and will help to shed any grout. With a stiff brush, sweep all concrete grout and debris off the bars to ensure no concrete becomes encrusted. The sooner the panels are scrubbed and cleaned after the concrete pour, the easier and quicker it will be to prepare them for re-use.

The panels will be supplied with as many bars in them as possible, which ensures a minimum of grout leakage between the bars. However, after a number of concrete pours, the free movement of the bars in the panel may become restricted and in practice this may be eased by removing one or two of the bars. Any ‘gaps’ caused by this will immediately be taken up by the remaining bars.